The first pianos were essentially harpsichords fitted with hammers that struck the strings, in place of the harpsichord's crow-quill plectra, which plucked them. The strings were made of metal — iron for the treble strings, brass or bronze for the bass — as were the tuning pins, bridge pins, hitch pins, nut pins, key pins, and various fasteners and levers. A small amount of wool cloth or felt served to quiet moving parts. The hammers on the first pianos had leather pads backed by wood or small rolls of parchment, and were attached to wooden shanks or stems. The remainder of the instrument would have been built of wood — cypress, pine, or spruce formed the soundboard and rim, while the pinblock, bridges, and hitch-pin rail were made of hardwoods such as hickory, beech, or maple. A century passed before this basic piano recipe began to change significantly.

Iron Bracing and Tempered Steel

Throughout the 18th century, the wire used in harpsichords and pianos would have been what today is called soft iron. In 1810, Pleyel of Paris patented the process of producing tempered steel wire, and its gradual introduction into pianos over the next 30 years may have constituted the first real step away from the original traditional materials used in pianos. Tempered steel wire could be strung at a higher tension than iron wire to produce the more powerful sound that was increasingly sought by musicians, and thus would have been viewed by many as an improvement over iron.

At about the time that tempered steel strings began appearing in pianos, so did iron bracing. Even with the lower-tensioned iron strings, the combined tension of all the strings on the structure of the piano was several thousand pounds — enough to cause the case of the instrument to eventually start coming apart. As early as 1800, there were a number of attempts to use iron tubes and bars, and iron hitch-pin plates, to brace the piano's structure against the tension of the strings. With the advent of tempered steel wire and the resulting general increase in string tensions, the search for an adequate bracing material took off in earnest. In 1825, Alpheus Babcock, a Boston piano maker, succeeded in having an iron piano frame cast in one piece for a square grand. By the end of the 19th century, virtually all piano makers had adopted this element, and today the one-piece, cast-iron plate is one of the signature features of the modern piano.

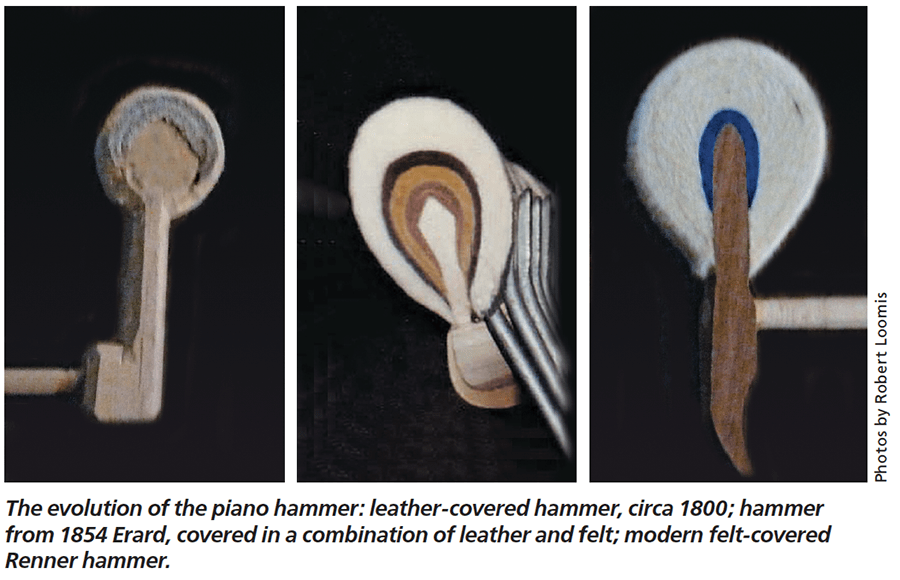

Leather vs. Felt Hammers

Piano hammer heads in the 18th-century English and Viennese schools of piano building were constructed of concentric layers of leather glued over a wooden molding. Leather was both flexible and firm, but came in many varieties of hardness or softness, which resulted in great varieties of tone quality. According to Rosamond E.M. Harding, in The Piano-Forte:Its History Traced to the Great Exhibition of 1851 (Heckscher, London, 1978), even as late as 1856 deer leather "was considered to be the most durable material for covering the hammer head; it would satisfy everyone if the skins were always of the best quality, of even thickness all over, and of even elasticity, which unfortunately was never the case." By then, experiments to find a more consistent hammer covering than leather had been going on for a long time, and the search included trials with cloth, cork, India rubber, sponge, and tinder. The first patent for felt-covered hammers was granted to Jean Henri Pape, of Paris, in 1826. For much of the second half of the 19th century, felt and leather were layered together in various configurations, but eventually felt — once a nontraditional material — became the new standard.

Keytops: Ivory or Plastic?

Sometimes a traditional material becomes unavailable and must therefore be replaced by a nontraditional material. Perhaps the best example of this is the replacement by plastic of ivory keytops. Although piano makers began using plastic keytops on cheaper instruments as early as the 1930s, and even on good grands as early as the 1960s, it wasn't until the passage of legislation in 1973 and 1989 banning the use, importation, and sale of elephant ivory that plastic became the de facto material for piano keytops.

The search for an alternative material for keytops may have begun, however, as early as the late 18th century. Harding lists several patents from 1788 to 1840 for covering piano keys with materials such as glass, enamel, bone, horn, mother-of-pearl, and porcelain. "It is unnecessary to enumerate more," says Harding; ". . . glass, porcelain, or enamel was to form a cheap substitute for ivory. The beautiful ivory itself was not thought to be as good as that which was plain and unfigured." Today, some makers describe their plastic keytops as synthetic ivory, and seek to formulate plastics with some of ivory's desirable properties, such as texture and the ability to absorb moisture.

Synthetic Leathers

Until fairly recently, buckskin was the material of choice for certain parts of the piano's action. Both the hammershank knuckle and the backcheck in the grand action were covered in buckskin, as was the hammer butt in the vertical piano action. Some manufacturers began using nontraditional materials to cover some of these parts as early as the 1960s and '70s, and there was a learning curve, to be sure. Baldwin's Corfam hammer-butt coverings became hard and noisy after several years' use, and the company routinely replaced them under warranty with Ecsaine, another synthetic material. In the 1960s, Steinway experimented with replacing not only the covering of the grand hammershank knuckle, but the entire knuckle, with a solid piece of hammer felt. After a few years of feedback about these experimental knuckles, Steinway returned to the more conventional buckskin covering.

Very recently, however, both the New York and Hamburg Steinway factories have replaced buckskin with Ecsaine for both the knuckle and backcheck coverings. As with the use of leather as a hammer covering 150 years ago, the problem was that the properties of buckskin vary from skin to skin. It was also difficult to find buckskin soft and supple enough to prevent action noise at both points. Ecsaine, on the other hand, has all the sought-after properties of buckskin, but is completely uniform from one piece to the next.

The Furniture

Most piano manufacturers now incorporate nontraditional materials in their cabinet parts. Laminated wood products, in place of solid or veneered wood, have become commonplace in both structural and nonstructural cabinet parts (as well as in soundboards). Engineered wood products such as medium-density fiberboard (MDF), and plastic trim find frequent use in place of wood in nonstructural areas. At least one European manufacturer of quality grands uses a paper-based material much like cardboard in nonstructural areas of the case, and I suspect that this material is used by other companies as well.

Piano finishes, too, have changed much over the years. The traditional piano finishes in the 18th and 19th centuries were shellac and varnish. Shellac, made from insect shells dissolved in alcohol, is a relatively nontoxic finish that, when damaged, is easily repaired. It is, however, difficult and time consuming to apply evenly in large quantities, and its highest expression, French polish, requires great skill.

Varnishes are made of various kinds of resins dissolved in oils such as mineral spirits. Exposed to light, varnish tends to darken and wrinkle as it ages, creating the "alligatored" appearance so often seen on early 20th-century pianos. A beautiful and durable coating, varnish was the piano finish of choice from the late 19th century until the development of cellulose lacquer in 1928. Lacquer, essentially a synthetic shellac made of cellulose dissolved in volatile solvents such as acetone, can be sprayed on and dries faster than varnish, which makes it attractive for use in a factory setting — but it is highly toxic.

In the mid-20th century, chemists developed polyurethane varnishes and polyester wood finishes. Polyurethane, a kind of synthetic varnish, is used on some pianos to create a satin finish. Polyester, basically a plastic, has become very popular, and is very likely to be the shiny, deep finish you see on new instruments. The hardest piano finish, polyester is extremely toxic in its liquid form, but is resistant to pretty much everything a piano might normally be exposed to, including water, alcohol, and scratching.

Plastic in the Action

All of this leads up to what may well be the most dramatic use of nontraditional materials in piano construction since the development of the modern piano in the last half of the 19th century. A few piano manufacturers, most notably Kawai and Mason & Hamlin, have invested heavily in research and development to design and produce plastic action parts for their pianos. Contrary to what one might think, the goal is not to save money, as both the research and development expenses and the cost of producing the parts are substantial. According to Bruce Clark, senior design engineer at Mason & Hamlin and its subsidiary piano-action company, Wessell, Nickel & Gross (WNG), "The only reason you do this is to make better parts. In 1850 wood was the high-tech best material for piano actions; that's no longer true."

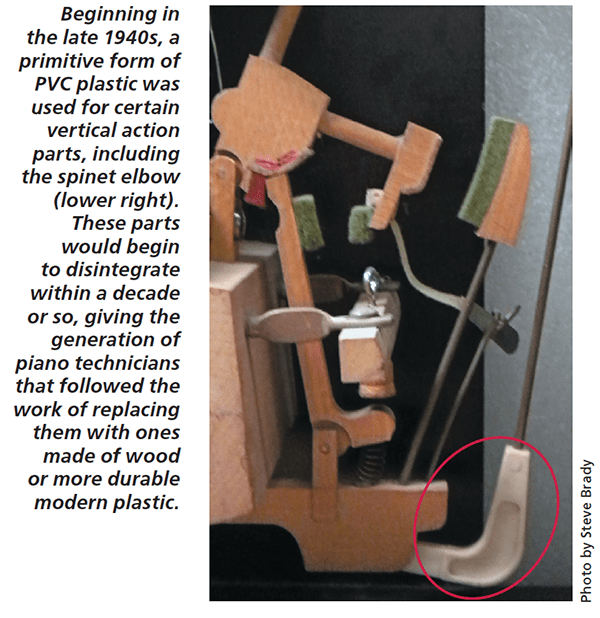

The first plastic piano action parts appeared in pianos built in the late 1940s, and because they were used only in smaller pianos, especially spinets, it can be inferred that the aim at that time was to save cost. However, these early plastic parts also appeared in console pianos made by the high-end Mason & Hamlin company, so there may have been other benefits to using plastic, such as uniformity and stability.

The first action parts made of plastic included the elbows (unique to spinet pianos), various action flanges, backchecks, and even damper levers. Unfortunately, all these early polyvinyl chloride (PVC) parts were doomed to failure because the plasticizers that kept the material pliable would gradually migrate out of the parts until they became brittle and prone to shatter, usually within five to fifteen years. As one who became a piano technician in the early 1970s, I was the grateful recipient of many plastic-elbow replacement jobs during my first several years in the business!

Plastics technology has come a long way since those early days. Kawai began using acrylonitrile-butadiene-styrene (ABS) for certain action parts in the late 1960s, and the material has proven extremely durable. According to Don Mannino, Kawai's director of technical training, "Kawai made the commitment early on to improve piano actions, both in terms of consistency of feel and reliability, and the early conservative application of ABS to upright action flanges has spread to upright hammer butts, wippens, and damper levers. In grands, the hammer flanges, wippen assemblies, and the entire damper underlever assembly is made from ABS." In the current Millennium III action found in Kawai's upper-level models, the ABS is reinforced with carbon fiber, making the parts stronger with less mass. The resulting action, according to Kawai, is more responsive to the player's intentions, including faster repetition. The use of plastic also allows Kawai to micro-engineer certain contact surfaces for ideal shape and texture, something that would be impossible with wooden parts.

State-of-the-Art Composites

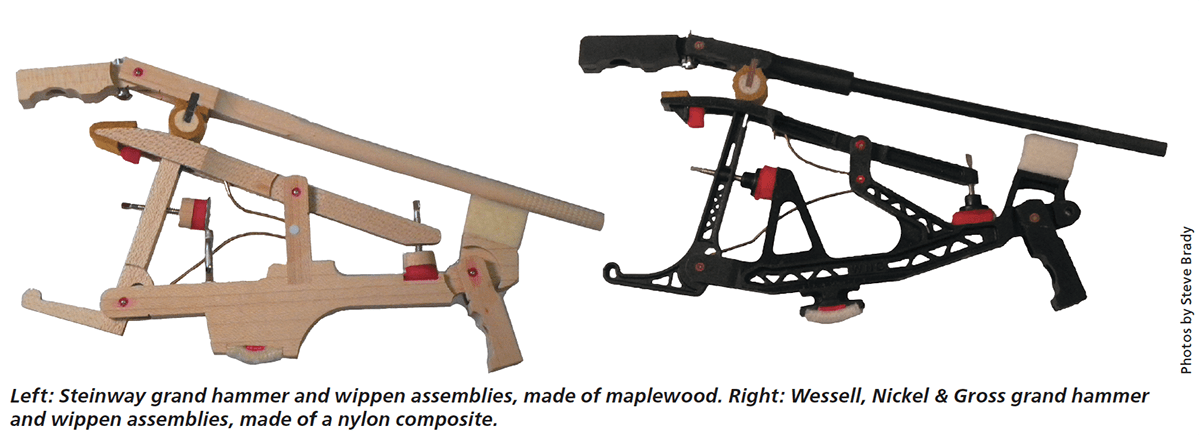

Mason & Hamlin, through its WNG subsidiary, has thrust the use of nontraditional materials into high gear. Engineer Clark makes a strong case for pursuing better parts by using nontraditional materials. "When you go to a new material, if you don't take advantage of its properties, there's no point in using it. In our case, the material (a composite of nylon and glass) is 10 times stronger than maple, but weighs only twice as much." By radically redesigning the wippen assembly to remove and redistribute mass, Clark is left with a part that looks like miniature bridge trusses; while still slightly heavier than a comparable maple part, it is many times stronger. "To reduce inertia, we've shifted the center of gravity closer to the center of rotation," he says. "It's not reasonable to do that with wood." Other advantages to using a modern composite in place of wood are that the composite is more consistent in both weight and strength, and is completely impervious to changes in moisture and temperature.

According to Mason & Hamlin co-owner Mark Burgett, the hammer shanks in the WNG action are essentially carbon-fiber tubes, which he says are not only stronger than traditional maple shanks, but also more consistent in flex strength. This consistency pays off in making the piano's voicing more consistent. "Much of what we have to do to the hammers to make the voicing more even is made necessary by inconsistency in the wooden hammer shanks," Burgett says. "If one shank is more pliable than another, the tone of that note will be darker and may include an unwanted noise element. With the carbon-fiber shanks, we find that much less hammer voicing is needed." Since January 2010, all Mason & Hamlin grand pianos have been equipped with all-composite top actions. All-composite grand damper actions are now available, and the company says that a composite vertical piano action is in the works. All of the WNG parts are also available to piano rebuilders.

Defending Tradition

At this point, most high-end piano makers still use wooden action parts in their best pianos. Steinway & Sons takes the stance that you don't argue with success:

Steinway & Sons has a long and successful history with the use of hard rock maple in our action parts. For more than 150 years, artists around the world have chosen the Steinway tone and touch as the standard of excellence.

These artists expect a certain sound and touch each time they play a Steinway piano that is unique to our instruments. We have a strong commitment to the world of music to ensure that these performance expectations continue to be met. With respect to this commitment, we at Steinway feel that our choice of materials in action parts influences not only the touch of the instrument but also uniquely contributes to the tone. The use of all natural hard rock maple action parts is a time-tested ingredient of the Steinway performance experience and we remain very comfortable with maple as the material of choice in our Steinway pianos, as we continue to build our pianos to a standard, not to a price.

Similarly, Bösendorfer states that the company "has always used traditional components and methods in crafting its instruments. There has been no reason to change the 180-year-old tradition of using organic and natural componentry."

Action Centers

Even when piano manufacturers have experimented with using plastic or composite action parts, they have usually stayed with traditional action centers — the pivot points on which individual action parts swing or rotate. Traditionally consisting of a center pin held fast in the wood of the main part, and surrounded by a wool cloth bushing in the smaller wooden flange (hinge), the action center's proper operation critically depends on the flange being able to move freely around the pin in a controlled manner. But since felt is highly susceptible to changes in humidity — it swells up and tightens in higher humidity and loosens in lower humidity — the feel of a piano action can vary dramatically from season to season. In extreme cases, an action exposed to high humidity will become heavy and sluggish, and keys may actually stick, while in very low humidity the flanges may become so loose that action noises develop.

This tendency of piano actions to react poorly to extreme humidity or dryness led Steinway & Sons, whose pianos were shipped to destinations as hot and humid as the tropics and as cold and dry as Siberia, to look for ways to protect the action centers from changes in humidity. Their initial solution, dating back to the late 19th and early 20th centuries, was to treat the wooden action parts with liquid paraffin, thus sealing the parts and at least slowing the passage of moisture into and out of the flanges. The problem with this approach was that, over a long period of time — decades, in most cases — the paraffin migrated into the wool bushings of the action centers, where it reacted with the metal center pins to create verdigris, a type of corrosion. Eventually, the verdigris would render the action sluggish, even unplayable.

In a very important next step, in 1962 Steinway pioneered the use of modern plastics in pianos with the introduction of Permafree™ action flange bushings made of Teflon. Replacing the traditional wool cloth bushings with an inert material that didn't react to changes in humidity seemed a revolutionary step toward ensuring a reliably free and consistent piano action. But in actual practice, the new bushings were far from trouble free — what Steinway didn't realize was that dimensional changes in the wooden flange would affect the Teflon bushing. As the flange swelled with humidity, it put more pressure on the Teflon, which in turn pressed tighter on the center pin, causing the action to feel heavy and sometimes sluggish. Conversely, when low humidity caused the flange wood to shrink, the Teflon bushing became loose in the wooden part, causing a noticeable click when the key was played. Steinway twice redesigned the Teflon bushings to overcome these problems, and the third iteration worked quite well. But in 1981, tired of bad press, and finding it difficult to educate piano technicians in the new methods required to service the Teflon bushings, the company replaced the solid Teflon with wool cloth that had been soaked in liquid Teflon, a process Steinway named Permafree II™. This process is still used today, with good results.

Now Mason & Hamlin has taken the idea of synthetic action centers to a new level. First, they have replaced the traditional brass or German-silver (nickel) center pins with stainless-steel needle bearings. "The needle bearings are much harder than traditional center pins," says Burgett, "and they're available in increments of one 10,000th of an inch, as opposed to increments of one 1,000th of an inch with traditional center pins. This gives us outstanding control of the fit." The other change was to replace the traditional wool cloth bushing with a composite material. The actual composition of that material is proprietary, says Burgett, who notes, however, that the new bushing material is harder than felt or Teflon and is very resistant to damage. "The new action centers are absolutely unchanged by humidity variations, and are very consistent from note to note. This means we have extraordinary control of friction and, therefore, of touchweight."

What's Next?

Other piano manufacturers, as well, are experimenting with composites. For example, the high-end German piano maker Steingraeber & Söhne is using carbon-fiber soundboards in its Phoenix System models. I even know of a few individuals who have attempted to build the entire structure of a piano — case, plate, pinblock, and soundboard — of composites, the dream being to create a lightweight grand piano that one or two people could easily pick up and put into a van. Such instruments would also conserve precious wood resources, and might stay in tune better than pianos constructed mostly of wood. But while the composite piano remains at this point only a dream, history has made one thing clear: As long as pianos continue to be built, nontraditional materials will have a place in their construction.