Three terms are often used in discussions of piano restoration work: repair, reconditioning, and rebuilding. There are no precise definitions of these terms, and any particular job may contain elements of more than one of them. It’s therefore very important, when having restoration work done on your piano or when buying a piano on which such work has been done, to find out exactly what jobs have been, or will be, carried out. “This piano has been reconditioned” or “I’ll rebuild this piano” are not sufficient answers. One technician’s rebuilding may be another’s reconditioning.

Repair jobs generally involve fixing isolated broken parts, such as a broken hammer, a missing string, or an improperly working pedal. That is, a repair does not necessarily involve upgrading the condition of the instrument as a whole, but addresses only specific broken or improperly adjusted parts.

Reconditioning always involves a general upgrading of the entire piano, but with as little actual replacement of parts as possible. For instance, reconditioning an old upright might include resurfacing the hammer felt (instead of replacing the hammers) and twisting (instead of replacing) the bass strings to improve their tone. However, defi-nitions of reconditioning can vary widely: Many technicians would consider the replacement of hammers, tuning pins, and strings to be part of a reconditioning job in which more extensive work is either not needed or not cost-effective; others would call such work a partial rebuild.

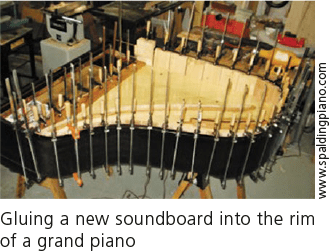

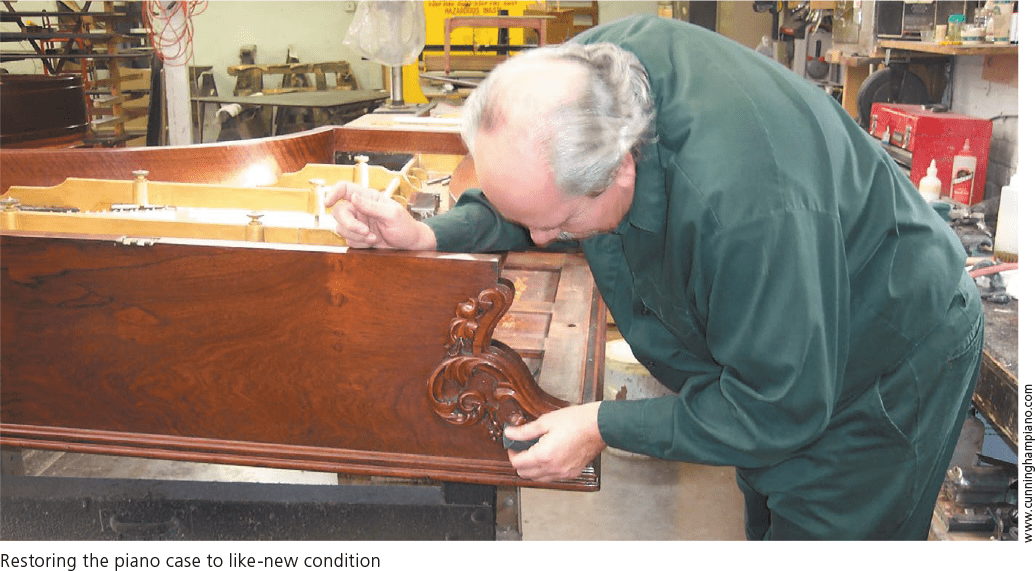

Rebuilding is the most complete of the three levels of restoration. Ideally, rebuilding means putting the piano into “like new” condition. In practice, however, it may involve much less, depending on the needs and value of the particular instru-ment, the amount of money avail-able, and the scrupulousness of the rebuilder. Restringing the piano and replacing the pinblock in a grand, as well as repairing or replacing the soundboard, would typically be parts of a rebuilding job. In the action, rebuilding would include replacing the hammer heads, damper felts, and key bushings, and replacing or completely overhauling other sets of parts as well. Refinishing the piano case is also generally part of the rebuilding process. Because of the confusion over the definitions of these terms, sometimes the term remanufacturing is used to distinguish the most complete rebuilding job possible — including replacement of the soundboard — from a lesser “rebuilding.” However, there is no substitute for requesting from the technician an itemization of the work performed.

When considering buying a rebuilt piano, or having a piano rebuilt, particularly an expensive one, the rebuilder’s experience level should count heavily in your decision. The complete rebuilding of a piano re-quires many dissimilar skills. The skills required for installing a sound-board, for example, are very differ-ent from those required for installing a new set of hammers or for regulating the action. Mastering all of these skills can take a very long time. In a sense, you should be shopping for the rebuilder as much as for the piano.

Many rebuilders contract out portions of the job, particularly the refinishing of the piano’s case, to others who have special expertise. Although this has always been so, more recently groups of technicians, each with his or her own business and shop, have been openly advertising their close, long-term collaboration with one another on rebuilding jobs. In a typical collaboration of this type, one person might rebuild the strung back or soundbox (soundboard, bridges, pinblock, strings, tuning pins, cast-iron plate); another would rebuild the action and do the final musical finishing, such as regulating and voicing; and the third would refinish the case. Collaboration of this kind is a positive development, as it means that each technician does only what he or she does best, resulting in a better job for the customer. But make sure you know with whom you are contracting or from whom you are buying, and which technician is responsible for making things right if problems arise.

It may occur to you that you could save a lot of money by buying an unrestored piano and having a technician completely restore it, rather than buying the completely restored piano from the technician. This is often true. But the results of a rebuilding job tend to be musically uncertain. That is, if you are particular in your taste for tone and touch, you may or may not care for how the instrument ultimately turns out. For that reason, especially if a lot of money is involved, you might be better off letting the technician make the extra profit in return for taking the risk.

Grand Piano Rebuilding Checklist

The following is a list of the tasks that might comprise a fairly complete rebuilding of a grand piano. Any particular job may be either more or less extensive than shown here, depending on the needs and value of the instrument and other factors, but this list can serve as a guide. See also The Piano Book for information about specific rebuilding issues pertaining to Steinway and Mason & Hamlin pianos.

Notice that the restoration can be divided into three main parts: the soundbox or resonating unit, the action, and the cabinet. The soundbox (also known as the strung back or belly) includes the soundboard, ribs, bridges, strings, pinblock, tuning pins, plate, and the structural parts of the case; the action includes the keyframe and action frame, keys and keytops, hammers, dampers, trapwork, and all other moving action parts; the cabinet includes cosmetic repair and refinishing of the case and of the nonstructural cabinet parts and hardware. Note that the damper parts that contact the strings are restored with the soundbox, whereas the damper underlever action is treated with the rest of the action.

There is very little overlap among the three types of work; each of the three parts could be performed alone or at different times, as technical conditions permit and/or financial considerations require. In a typical complete rebuilding job, restoration of the soundbox might comprise 45 percent of the cost, the action 30 percent, and the cabinet 25 percent, though these percentages will vary according to the particulars of the job.

Soundbox or resonating unit

- Replace or repair soundboard, refinish, install new soundboard decal (if not replacing soundboard: shim soundboard cracks, reglue ribs as necessary, refinish, install new soundboard decal)

- Replace pinblock

- Replace bridges or bridge caps

- Replace or ream agraffes, restore capo-bar bearing surface

- Refinish plate, paint lettering, replace understring felts

- Replace strings and tuning pins, tune to pitch

- Replace damper felts, refinish damper heads, regulate dampers

Action

- Replace hammers, shanks, and flanges

- Replace or overhaul wippen/repetition assemblies

- Replace backchecks

- Replace front-rail key bushings

- Replace balance-rail key bushings or key buttons

- Replace or clean keytops

- Replace key-end felts

- Clean keys

- Clean and refelt keyframe

- Replace let-off felts or buttons

- Clean and, if necessary, repair action frame

- Regulate action, voice

- Overhaul or replace damper underlever action and damper guide rail

- Overhaul pedal lyre and trapwork, regulate

Cabinet

- Repair music desk, legs, other cabinet parts, as needed

- Repair loose or missing veneer

- Strip and refinish exterior; refinish bench to match piano

- Buff and lacquer solid-brass hardware, replate plated hardware

“Vintage” . . . or New?

“Vintage” pianos are those made during the golden years of piano-making in the United States — roughly, from 1880 to World War II. More specifically, the term usually refers to the Steinway and Mason & Hamlin pianos made during that period, though it’s occasionally applied to other great American makes as well. In the last few decades the demand for these pianos, and consequently their prices, has mushroomed due to a (until recently) strong economy, increased entrepreneurial activity on the part of rebuilders and piano brokers, allegations by rebuilders and others that today’s new pianos are not as well made as the older ones were, and the purchase of many older Steinways by Steinway & Sons itself for rebuilding in its factory.

What makes these vintage pianos so alluring? Many musicians and technicians believe that these instruments, when rebuilt, sound and play better than new pianos. However, no one knows for sure why this should be so, since most of the components in the piano are replaced during rebuilding. Some point to the fact that Steinway operated its own plate foundry until about World War II, afterward using a commercial plate foundry (which it now owns). Because this radical change in the manufacture of such an important component roughly corresponds with the end of the vintage era, and because the plate is one of the few original parts to survive the rebuilding process, some speculate that it holds the key to the difference. Others say it has to do with changes in the quality of the wood available to Steinway and other companies. Still others say it wasn’t any single thing, but rather a combination of many fortuitous factors, including extremely skilled and talented craftsmen, that enabled these companies to make such special pianos during that period, but allegedly not afterward (though that doesn’t explain why the rebuilt ones from that period should be better).

Steinway & Sons, for its part, disputes the entire idea that older Steinways are better, dismissing it as a romantic notion spread by purveyors of those pianos in their own financial interest. The company says it has done extensive testing of both plates and woods, and the idea that the older plates and woods were better has no scientific basis. It says it has also carefully inspected hundreds of older Steinways at its factory rebuilding facility, which is the largest Steinway rebuilding facility in the world, and finds no evidence that the older pianos were built better than today’s — in fact, it believes that just the opposite is true. Steinway acknowledges that some pianists may prefer the sound of specific older pianos for subjective artistic reasons, but says that those considering the purchase of a restored, older instrument should do so to save money, not to seek better quality.

For more discussion of this topic, and of specific technical issues applicable to the rebuilding of a Steinway or Mason & Hamlin, please see The Piano Book.